Retraced is revolutionizing the fashion industry by empowering companies to gain full visibility into their supply chains through advanced traceability technology. As a leading traceability platform, Retraced is playing a pivotal role in helping brands navigate the complexities of sustainable sourcing and responsible production.

In this special conversation with BCome, Phillip G. Mayer, Co-Founder of Retraced, shares valuable insights into the evolving role of supply chain transparency. He discusses the growing demand for traceability in fashion and how brands are leveraging technology to meet new challenges, align with sustainability goals, and build stronger relationships with customers in an increasingly conscientious market.

In recent years, how have fashion brands’ efforts towards improving supply chain traceability evolved, and what key milestones have you observed in the industry?

Excel tables did a good enough job in the past, but we live in an era where brands’ expectations are much higher now as they strive towards sustainability in a more comprehensive way

Phillip G. Mayer, Co-Founder of Retraced

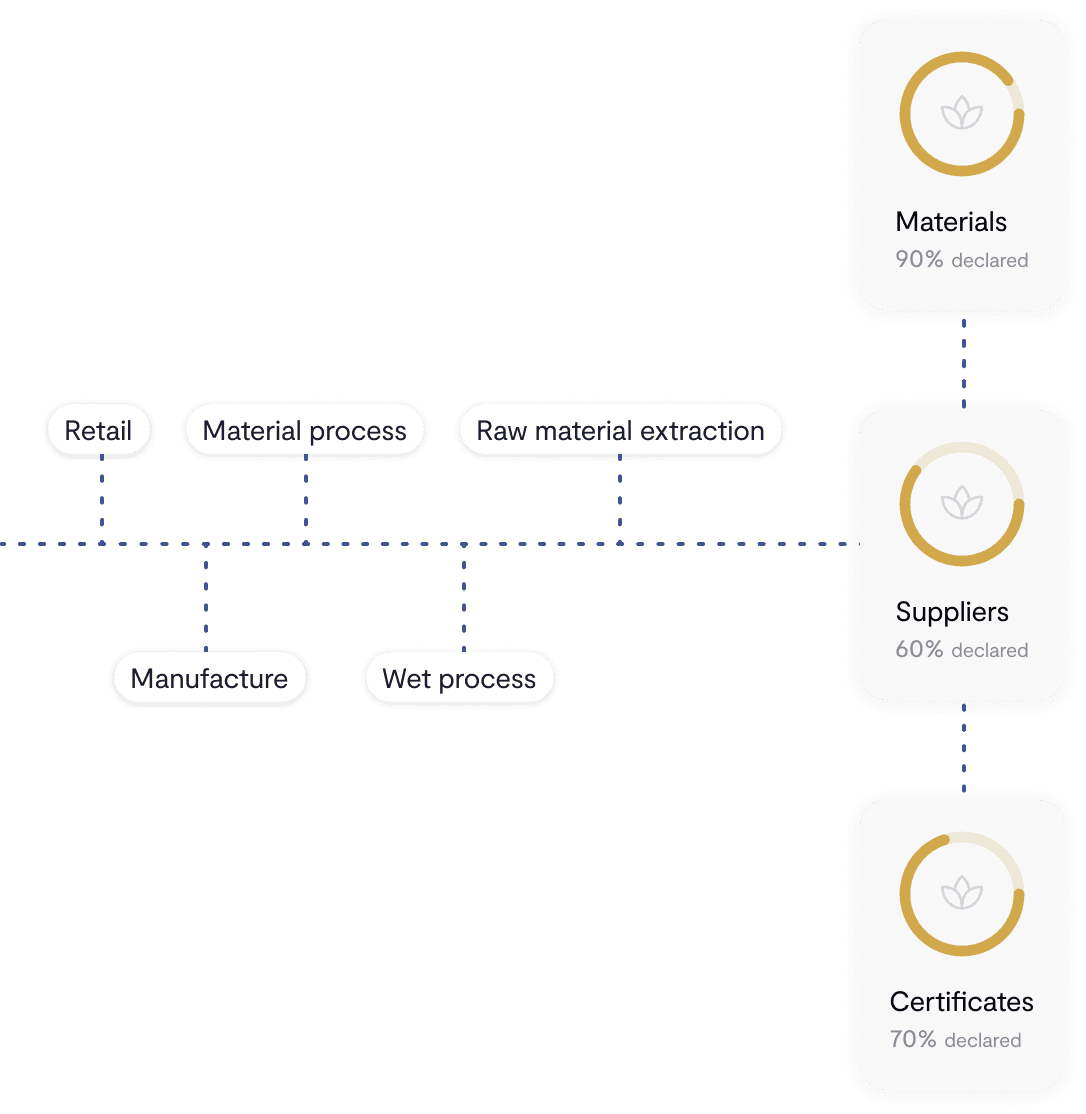

P. Over the past few years, we’ve seen remarkable progress in the way fashion brands approach supply chain traceability. Initially, many brands focused on mapping their first-tier suppliers only, meeting the most basic transparency requirements. Now, with stricter regulations and more critical consumers, we see fashion brands take a much broader approach, looking not only at more tiers of suppliers but also going into tracing their products, often down to the raw materials. To achieve this, more and more brands need to rely on tech platforms like Retraced to digitise their supply chains. This is a must have to enable industry collaborations and set the right responsible sourcing standards. Excel tables did a good enough job in the past, but we live in an era where brands’ expectations are much higher now as they strive towards sustainability in a more comprehensive way.

Retraced has worked with influential brands like Tom Tailor, Victoria’s Secret or Desigual, what is the ultimate goal driving these brands to trace their supply chains?

Traceability helps the brands run their businesses better aligned with their CSR goals and shows they’re serious about leading the way toward a more sustainable future

Phillip G. Mayer, Co-Founder of Retraced

P. For brands like these, traceability is about much more than just ticking boxes for compliance. These companies want to ensure they’re meeting new regulations and building trust with customers at the same time. Customers who care deeply about ethical and sustainable practices. It’s also about reducing risks in their supply chains—if there’s an issue, they want to catch it early and fix it. At the same time, these efforts align with their sustainability goals, like improving their environmental impact and sourcing materials responsibly. Traceability helps them run their businesses better aligned with their CSR goals and shows they’re serious about leading the way toward a more sustainable future.

Despite growing awareness about the relevance of traceability and transparency, what are the biggest obstacles fashion companies face when it comes to implementing effective traceability systems?

P. Implementing traceability systems is a complex undertaking, and companies face several key challenges. The first is supply chain complexity—fashion supply chains are global and involve multiple tiers of suppliers. The second challenge is data integration—collecting and standardising data from various sources is time-consuming. That is not surprising as brands rely on their supplier’s data and data needs to be collected, then centralised to enable the right decisions to be made. Third, cost can be a crucial factor for brands, as implementing robust systems requires investment in technology and expertise. Finally, supplier engagement remains a challenge; not all suppliers are willing or able to provide the required transparency. Overcoming these challenges demands a combination of the right tools, education, and industry partnerships that promote trust across the supply chain.

With new regulations like the EU Corporate Sustainability Due Diligence Directive (CSDDD) and the Digital Product Passport (DPP) coming into play, how do you foresee these legislative changes impacting fashion in the coming year?

P. These regulations are a chance to completely transform the industry. The EU CSDDD and DPP will push brands to prioritise transparency and accountability like never before. In practice, this means brands will need to provide detailed insights into their product life cycles, from material sourcing to production and distribution. Compliance will require operational changes, such as enhanced data collection and greater collaboration with suppliers. On the positive side, these changes will level the playing field and reward brands that have always invested in sustainability and ethical practices. I see this as an opportunity for the industry to strive for higher standards, paving the way for a more sustainable future.

Fashion companies sometimes struggle to fully use the data collected across their supply chains. Looking ahead to 2025, how do you think brands can become more proactive in integrating this information into their daily operations?

P. To really make use of supply chain data, brands need to make it part of their everyday decisions. By 2025, I think we’ll see more companies using this information to guide how they choose suppliers, design products, and market to their customers. Technologies like AI can help make sense of large amounts of data, but just as important is making sure suppliers are on board and that the data is reliable. The key is to keep things practical—focusing on what will drive real improvements. When brands treat traceability data as a tool for smarter decision-making rather than just an obligation, they’ll see better results and build stronger relationships with their customers.

To really make use of supply chain data, brands need to make it part of their everyday decisions. By 2025, I think we’ll see more companies using this information to guide how they choose suppliers, design products, and market to their customers

Phillip G. Mayer, Co-Founder of Retraced

This interview offers an exclusive preview from the Sustainability Handbook 2025: Fashion’s Breakpoint. Dive into the key challenges the fashion industry will face in the upcoming months and discover how BCome can help you address them with actionable solutions. Whatever your business requires, we’re here to offer personalized support designed to meet your unique needs.

Phillip G. Mayer is the Co-Founder of Retraced.