Despite the implementation of eco-design principles and the fashion industry’s relentless quest to reduce its environmental footprint, there is one element that is inherent in the clothing sector: textile waste. Legislative pressures and the climate emergency highlight the need to innovate to use new recycling technologies that allow the use of textile waste as a raw material. Obtaining quality materials that can be recycled again must be the primary goal to guarantee the effectiveness of any circular strategy. Below we tell you the keys for your fashion business to keep its textile waste away from landfill.

The Waste Framework Directive will force EU Member States to collect textile waste separately before January 2025

According to the Ellen MacArthur Foundation, in the last 20 years, the fashion industry has doubled its production volume. Today we consume twice as much clothing as two decades ago. Garments are worn half as often and only 13% of the total material input is recycled in some way after clothing wear, with most ending up in landfills or incinerated. The environmental consequences of this overconsumption are alarming. A problem that emits 20 tons of CO2 into the atmosphere for every ton of discarded textiles.

Given this context, it’s not surprising that the European Union seeks to regulate the implementation of circular initiatives to reintroduce the waste generated by the textile industry into the production cycle. The percentage of textile waste collection in the EU is approximately 25%. However, the review of the Waste Framework Directive will force Member States to collect this textile waste separately before January 2025. It’s time for your fashion business to tackle the challenge before the deadline is reached.

Before getting into the matter, it’s essential to analyze the origin of waste in the fashion industry. Identifying where your company’s waste comes from can help you both reduce it and have greater control over its processing.

- Pre-consumer or post-industrial waste. This is waste from the manufacturing process of a product. From the waste derived from the extraction of raw materials to the waste generated during manufacturing.

- Post-consumer waste. Textile waste mainly comes from garments discarded by consumers. It’s estimated that, on average, clothing is discarded only after approximately 3 years of use.

Post-consumer waste is a great challenge for textile companies, since companies don’t have direct control over it. Educating the consumer to prevent clothing from ending up in the trash is essential to reduce the volume of textile waste in landfills. The correct disposal of garments must be taught to allow efficient sorting and collection of waste, since the sorting processes of this waste are still carried out mostly by hand. A procedure that also makes it difficult to identify the fibers that make up each garment.

Despite obstacles to textile recycling new recycling technologies are making progress

In this sense, fashion still has a long way to go to find the technological solution that allows the fast and cheap automation of the sorting of textile waste with the aim of facilitating its recycling. Costs and timings are the main barriers that the fashion industry must fight against if it wants to scale circularity to the entire sector.

Despite obstacles to textile recycling such as inefficient waste collection and sorting systems or the low price of virgin materials, new recycling technologies are making progress.

Today, there are two main ways to recycle fibers. Below we analyze what they consist of and what are the technological innovations that are allowing both recycling methods to evolve.

Mechanical recycling

It consists of crushing the material to obtain practically a fiber that can be spun again. However, this grinding process shortens the fiber and weakens its quality. Because of this, mechanically recycled fibers often need to be mixed with virgin fibers and have limited circularity.

- Higher quality mechanical recycling. Thanks to technology, many factories can now create natural fibers of similar quality to virgin materials through mechanical recycling, without the need to mix virgin content. This is the case of Resilk®, a new type of fiber made from 100% recycled silk.

Chemical recycling

It involves a process that depolymerizes the material, so that only the desired raw material is recovered to produce new filaments, which are then transformed into threads. Chemically recycled fibers can achieve the same quality as virgin fibers and can be recycled multiple times without losing quality.

- Chemical recycling for synthetics. Technologies to chemically recycle synthetics have become more accessible in recent years. Now we can use recycled nylon from fishing nets. In this way, it’s increasingly common to find Econyl® in a wide range of garments, as is the case with some of the collections made by Ecoalf.

- Chemical recycling for mixed fibers. Companies such as Worn Again Technologies already allow blended fibers such as polyester and cotton to be separated and recovered from discarded clothing to produce virgin-equivalent raw materials suitable for ongoing recycling.

- Chemical recycling for natural fibers. The technological advances achieved by innovative companies have made the chemical recycling of natural fibers possible beyond the laboratory. Among other examples, we find Refibra™, produced from a mixture of chemically recycled cotton waste and eucalyptus wood. It’s the first cellulose fiber that includes recycled material that can be produced on a commercial scale and that we find in fabrics from brands such as Thinking MU or Zelles.

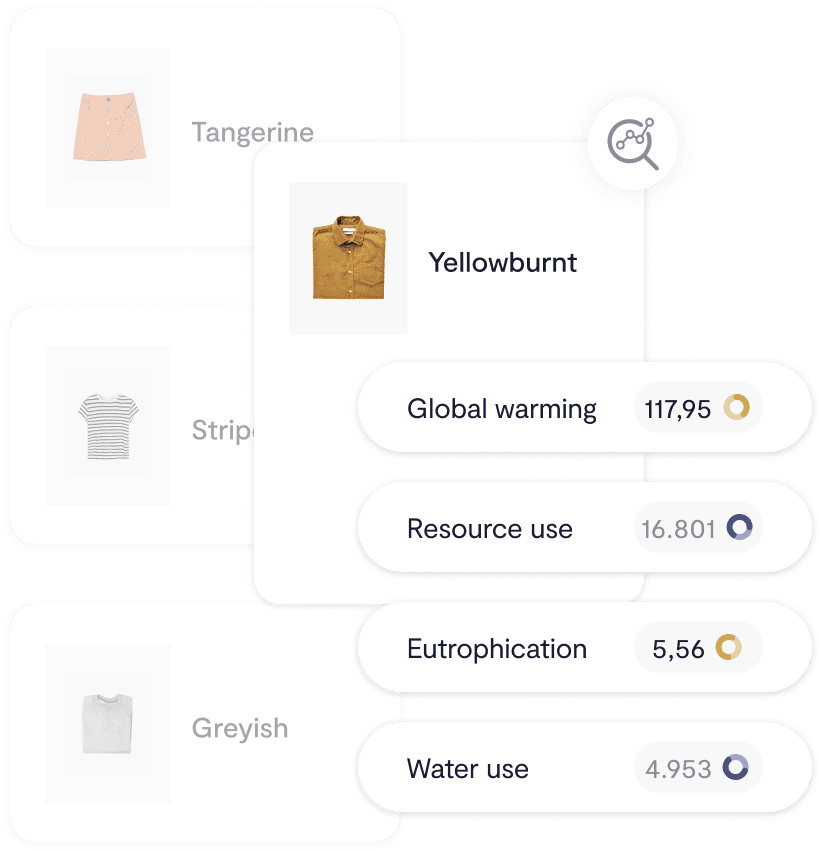

Recycling innovations are gaining momentum and funding gaps are being filled to support commercial scaling of these technologies. At BCOME we want to encourage you to eliminate the concept of waste from your fashion business, which is why we are developing a new product, the Material Circularity Indicator (MCI). A tool that will allow you to identify the potential of your textile resources so that they cycle repeatedly through your supply chain. Dare to be part of the sustainable transformation!