There is an undeniable reality: the planet’s resources are limited and they are running out. For years, the fashion industry has exploited natural resources excessively, leading to serious supply problems to sustain the current pace of production in the textile sector. In the midst of this supply crisis, ecodesign emerges as a crucial element to maximize the utilization of our resources and ensure minimal impact on the environment. In this article, we will explore strategies to address resource scarcity in fashion and how next-generation materials can pave the way towards a more sustainable future.

It is imperative to abandon outdated practices and turn to innovation as the key to addressing resource scarcity

From the disappearance of the Aral Sea to the dramatic reduction of Lake Urmia in Iran, a direct consequence of excessive irrigation for cotton production, intensive resource consumption has resulted in an increasingly evident scarcity of conventional materials used by the fashion industry. The recent rise in cotton prices serves as a clear indicator of this scarcity, and the increasingly frequent natural disasters due to climate change in key countries of the supply chain offer little hope for short-term recovery.

In light of this situation, it is imperative to abandon outdated practices and turn to innovation as the key to addressing resource scarcity.

Focus on new materials to move forward

Fortunately, in recent years, brands have introduced innovative materials that showcase the progress of eco-design in the fashion industry. The adoption of sustainable principles from the design stage is driving the creation of garments made with innovative materials, aiming for a more responsible future.

Major textile groups are venturing into purchasing a larger volume of recycled and sustainably sourced materials. However, there is still a perceived need to increase investment in strategies that promote the growth of recycling, as well as circular business models.

The recent bankruptcy of Renewcell, a leading company in textile-to-textile recycling, raised concerns about the viability of recycling technologies. However, just a week later, H&M, one of the company’s main clients, announced the creation of Syre. This new entity will be responsible for supplying the textile giant with recycled textile materials. This swift action demonstrates that the fashion industry relies heavily on these recycled materials to continue growing.

A prime example of this is one of our main clients, Ecoalf. For years, they have relied on Econyl, a regenerated nylon fiber made from nylon waste such as used fishing nets, discarded carpets, and industrial nylon waste, to create their products.

Given that raw materials can account for up to two-thirds of the climate impact of a fashion brand, ensuring access to sustainable materials is essential. However, according to a report published by Boston Consulting Group (BCG) in collaboration with Textile Exchange and Quantis, the demand for low-impact raw materials could exceed supply by up to 133 million tons by 2030.

This is because 85% of market-leading brands have publicly announced decarbonization objectives for their supply chains. Additionally, it is expected that over 35 new sustainability-related laws will come into effect within the next two to four years, encompassing import restrictions, product design guidelines, labeling requirements, among other obligations. This further underscores the necessity of having next-generation materials available.

Despite the increasing number of commitments and decarbonization objectives across the fashion industry, Tier 4 suppliers have not yet received a clear enough signal that brands are willing to commit and invest in more sustainable materials. Consequently, raw material producers lack incentives to take on the risks associated with increasing supply, which could result in a potential shortage of innovative raw materials.

Fashion brands must take immediate action to invest in the supply of sustainable raw materials, thereby ensuring resources and adapting their business models towards a sustainable future.

Devastating consequences in the face of the scarcity of next-generation materials

The fashion industry is in grave danger if it doesn’t support investment to scale up innovative materials:

- A shortage of environmentally friendly materials could affect their availability and cost within the industry. If there is a lack of supply of sustainable materials, companies may face difficulties in acquiring them in enough quantities to meet the demand for sustainable products. This could lead to an increase in the prices of these materials, which in turn could make the end products more expensive for consumers. Additionally, the scarcity of these materials could force companies to resort to less sustainable alternatives, thereby counteracting efforts to reduce the environmental impact of the industry.

- The lack of an increase in these materials could lead to non-compliance with upcoming regulations. If companies do not increase their use of low environmental impact materials to comply with stricter regulations, they could face fines and legal penalties. Furthermore, non-compliance with these regulations could damage the company’s reputation and its relationship with environmentally conscious consumers.

- Brands that do not invest in these resources risk falling behind competitors. Consumers are increasingly aware of the environmental impact of their purchasing decisions and prefer brands that demonstrate a commitment to environmental protection. Therefore, companies that don’t invest in expanding these resources may lose market share and customer loyalty to competitors who do.

This will require brands to reconsider their product offerings, strengthen relationships with suppliers, and foster company-wide commitment, which could take years.

Key actions to combat resource scarcity

To prevent your business from being caught in a cycle of raw material scarcity and difficulties in reducing its environmental impact, we provide strategies to address resource scarcity in the fashion industry and pave the way towards a more sustainable future:

- Implement traceability systems for each stage of the supply chain, from raw materials to the final product. This helps identify potential risks, such as unfair labor practices or negative environmental impacts, and enables timely corrective actions. Fully understanding the impacts of materials will allow you to make informed decisions about their use and continuously seek more sustainable alternatives.

- Base your decisions on data and solid scientific evidence regarding the environmental and social impacts of the materials used. This not only ensures the credibility and transparency of the company’s actions but also helps meet the expectations of stakeholders, such as customers and investors who advocate for sustainability.

- Diversify the portfolio of materials used. Focus on reducing vulnerability to potential scarcities, price fluctuations, or regulatory changes. This ensures that your company is prepared to adapt to changes in the economic and environmental landscape, maintaining stable and sustainable operations in the long term.

- Build a business model that leads towards triple bottom line gains. Develop solid arguments demonstrating how adopting sustainable practices benefits not only the company but also its suppliers and the environment. This may include cost savings, improvement of brand reputation, stronger relationships with suppliers, and positive contributions to the environment.

- Encourage collaboration and transparency with suppliers in the supply chain. This involves establishing long-term relationships based on trust and mutual commitment to continuous improvement.

- Provide access to tools to engage all employees in the path towards sustainability. Ensure that every team member is aligned with the company’s goals and can actively contribute to the implementation of sustainable practices across all areas of the organization.

Regarding basing your decisions on data and solid scientific evidence, at BCome, we have the capability to develop custom datasets to evaluate the impact of your next-generation materials. These personalized datasets are modeled based on an inventory collection form where your supplier completes the primary data.

Thanks to our ability to go one step further and assess the specific impact of certain raw materials or processes used, many of the brands working with BCome can more accurately determine the footprint of their most innovative materials.

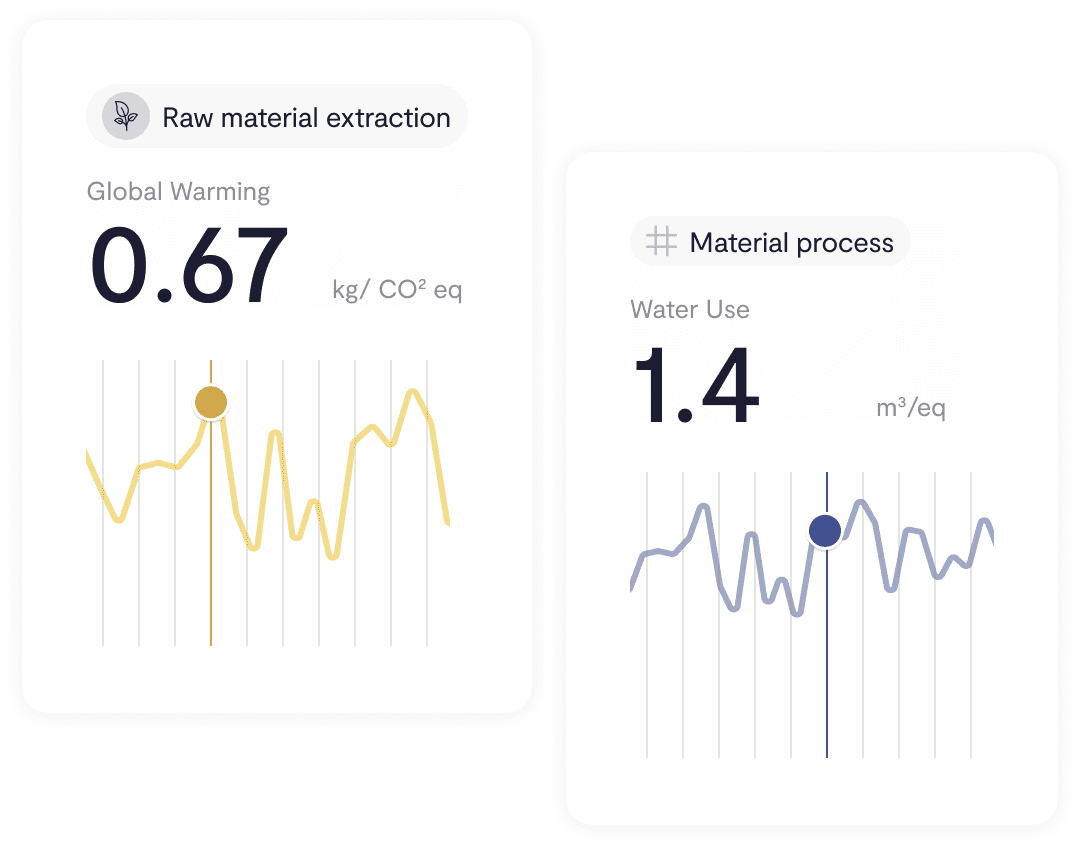

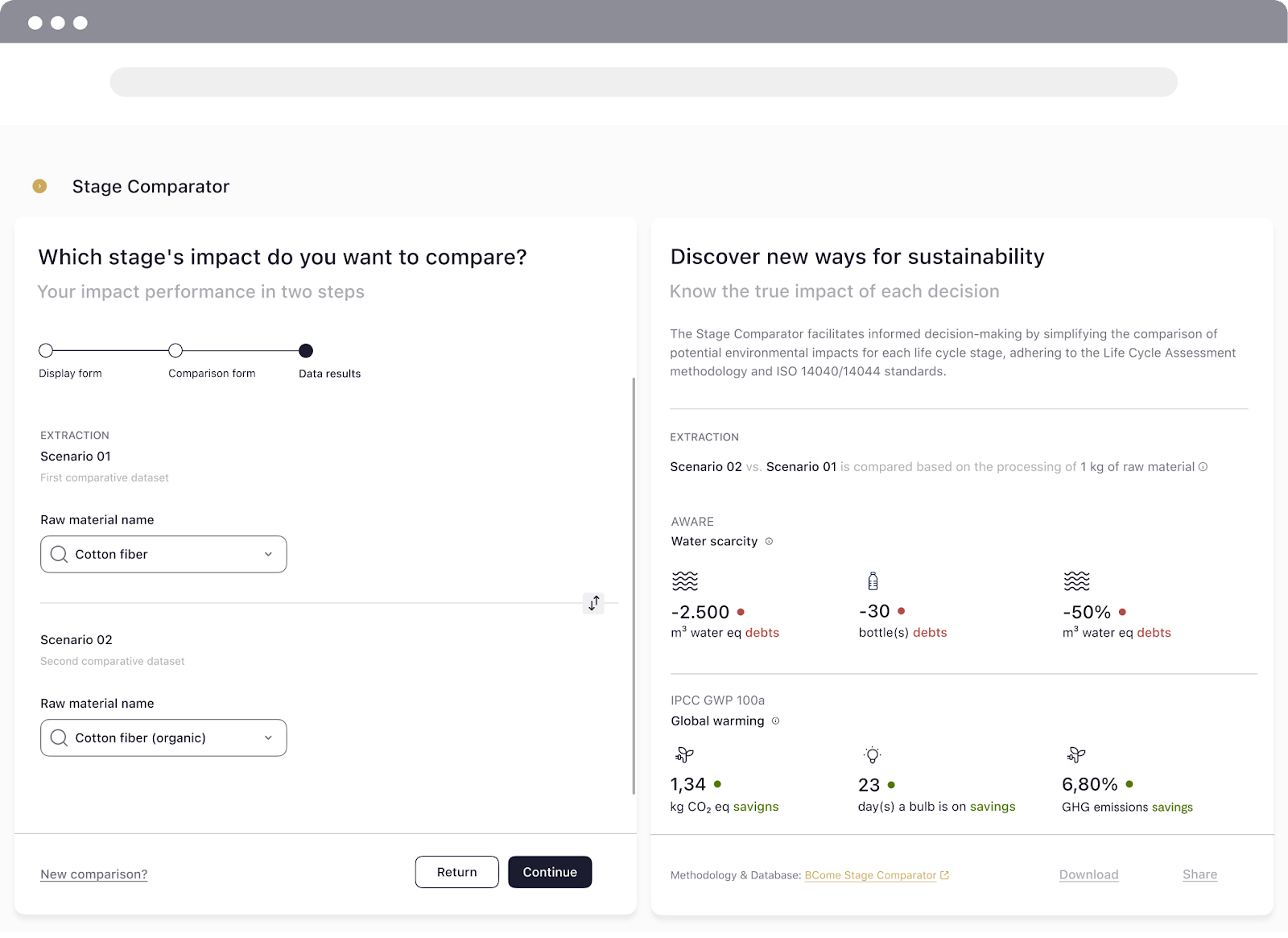

At BCome, we are aware of the need to find alternatives with similar performance to conventional fabrics and that also have a lower environmental impact. For this reason, we offer our Stage Comparator, an independent tool based on Life Cycle Assessment that allows you to quickly and easily compare the environmental footprint of two different scenarios for each stage of your supply chain, including fabric selection.

Additionally, we are also working on a new tool that will allow you to accurately forecast the environmental impact of your designs before creating your products, our Impact Simulator. This tool for designers will calculate the impact of your product so you can make informed decisions before creating it. By integrating advanced simulations, this functionality empowers designers to visualize the environmental consequences of their designs, making it easier for sustainable creations to materialize.

If you’re looking to make your fashion brand a reference point for change across the industry, at BCome, we offer solutions to help you become a market leader. Want to learn more? Let us show you!