At the end of 2021, we were able to see how the state of the fashion industry’s supply chains forced the transformation of conventional supply systems. The trend that began after the pandemic was accentuated during the last quarter of last year with the collapse of the main ports in China, the shortage of containers and the increase in the price of raw materials. Half a year later, the consequences of these problems are still present. Find out what are the main obstacles that your business purchasing department could be facing and 5 ways to improve the management of your value chain to guarantee its efficiency.

The huge lack of visibility makes proper supply management difficult

If there is one reality that the vast majority of fashion businesses experience, it’s the complexity of their supply chains. The number of processes that a garment undergoes are multiple, from the extraction of raw material to its end of life. This, together with the large relocation of production chains, generates a huge lack of visibility that makes proper management of supply difficult.

Fashion is an industry of time and cost, where quantity comes before quality. A loop of accelerated production cycles, uncontrolled outsourcing, impossible deadlines, unmanageable cost pressures and unsustainable margins. A cluster of circumstances that configure some of the most common problems in the supply of the textile industry:

Difficulty in having raw materials. The increase in transportation costs and the decrease in production, causes a shortage of materials. Much of the textile comes from Asia and local productions don’t have the extension or the resources to supply all the demand for raw materials.

Demand instability. The fashion industry is volatile in nature, which makes it difficult to forecast what production should be. As a consequence, the businesses assume the costs derived from not having adjusted their offer with the real demand.

Less tight delivery times. In order to reduce operating costs, it’s common for fashion companies to outsource production to countries located in Asia, where the proximity to the origin of the raw materials is usually greater. However, this also presents a challenge in terms of the time it takes for products to be available at the point of sale.

Transportation problems. You don’t have to experience the consequences of a pandemic to find setbacks in managing the transportation of an ordinary supply chain. A simple 24-hour delay or bottleneck at one of your distributor’s sorting centers has a ripple effect on product availability.

All these difficulties are linked to the lack of transparency in supply chains. The problems described above are not only an economic danger for fashion businesses, but also lead to high environmental and social risks in the industry. We’re facing a turning point where knowledge of the supply network must be a priority for the textile sector.

Here are 5 tips to efficiently manage your value chain:

1. Traceability to gain knowledge

Obtaining the information related to each of the stages of the product’s life cycle provides transparency and knowledge to identify which are the critical points on which action must be taken as a priority. Traceability is a long-term path that involves collaboration between the different agents in the chain. Providing visibility to suppliers takes a lot of pressure off communication and planning for upcoming inventories.

2. Performance evaluation from a multidisciplinary perspective

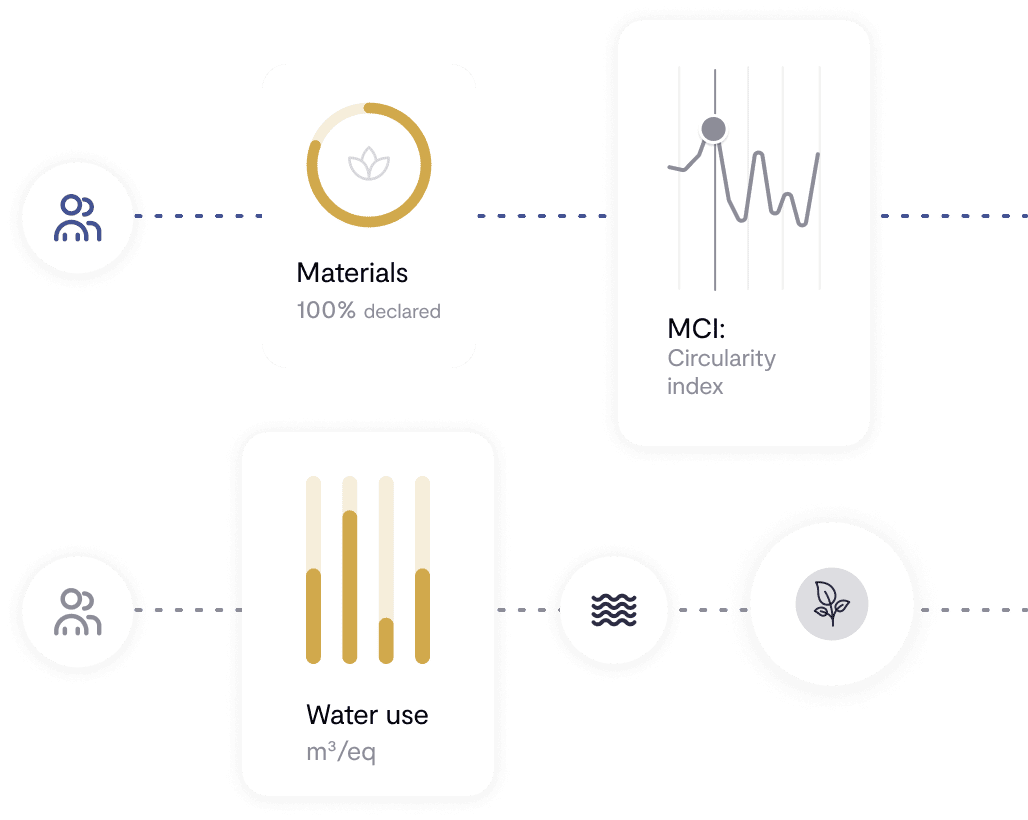

Developing the analysis of the environmental, social and economic impacts of the entire value chain will allow you to comprehensively quantify the current and potential impact of your products throughout their entire life cycle. Thanks to the metrics calculated from a Life Cycle Assessment (LCA), Social Life Cycle Assessment (S-LCA) and Life Cycle Cost Analysis (LCC), brands can implement solutions that improve efficiency of the supply chain, preventing a problem from moving to later stages.

3. Analysis of internal flow systems

It may be difficult to identify where your supply chain efficiency issues are coming from. If so, perhaps now is a good time to look at how value chain oversight is being handled internally. An ideal situation to assess the ambitions of those responsible for supply. Sometimes, unattainable goals are promoted that can have the opposite effect to the desired one.

It’s essential to trust professionals who have a comprehensive vision of the solutions applicable to supply chain management

4. Collaboration with trusted partners

Isolated solutions are often used when a specific need is detected in the value chain. However, instead of going to experts at very defined moments, it’s important to work proactively with them to detect possible changes that could optimize supply chain processes. It’s essential to trust those professionals who have a comprehensive vision of the solutions applicable to supply chain management.

5. Act with strategy

Increasing the efficiency of the value chain is not something immediate. It’s a continuous work, which implies developing a comprehensive plan that guarantees the achievement of the defined objectives. A good strategy serves as a guide in making key investments in the supply chain, to establish a solid distribution plan, define what the communication channels will be, as well as to identify risks and opportunities.

Finally, it’s important to mention that these five recommendations won’t only have a positive impact on the management of your supply chain, but also on optimizing its impact. Sustainability is closely linked to efficiency, what is good for the planet and people is also good for your business.

BCome technology enables businesses like yours to take control through planning and management tools, in order to build responsible supply systems and ensure transparency throughout the value chain. Do you want to reinvent your supply chain through sustainability? Contact us!