As margins become tighter in the fashion industry, it’s common for purchasing departments of textile companies to look for innovative solutions to drive cost savings without compromising product quality. In this scenario of critical competitiveness, BCome’s newly released PLM becomes a revolutionary tool thanks to its ability to boost your supply chain operations and achieve significant cost optimizations. In this article, we explore how your fashion business can use our PLM to achieve more cost efficiency in your supply chain.

If you were lacking arguments to implement a PLM in your fashion company, here are 5 economic benefits that BCome’s latest traceability solution makes available to your company:

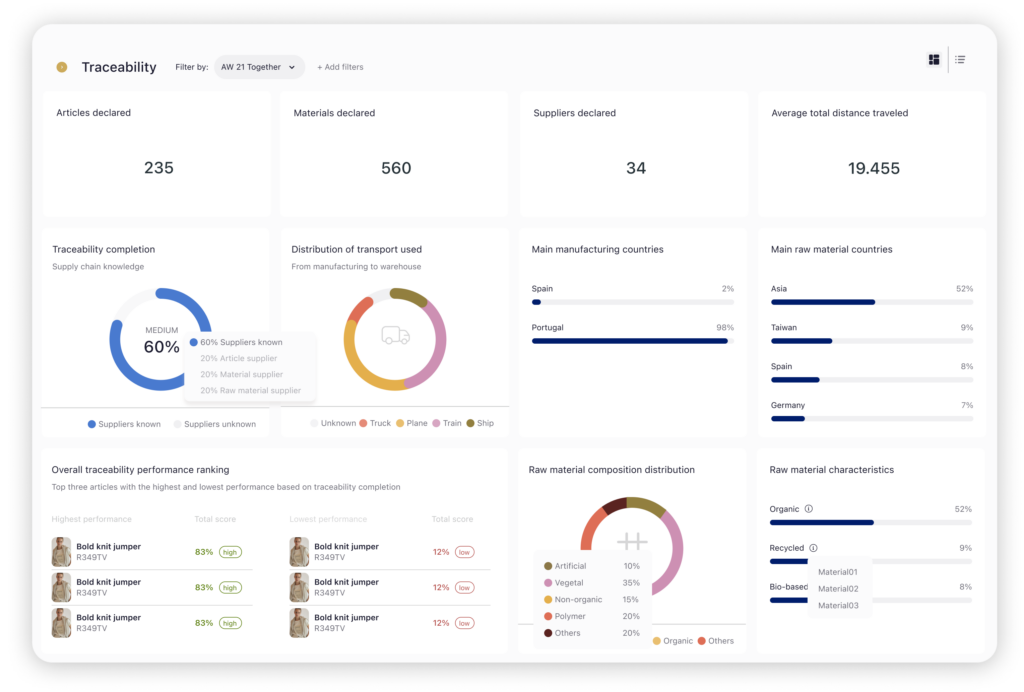

BCome’s PLM becomes a revolutionary tool thanks to its ability to boost your supply chain operations and achieve significant cost optimizations

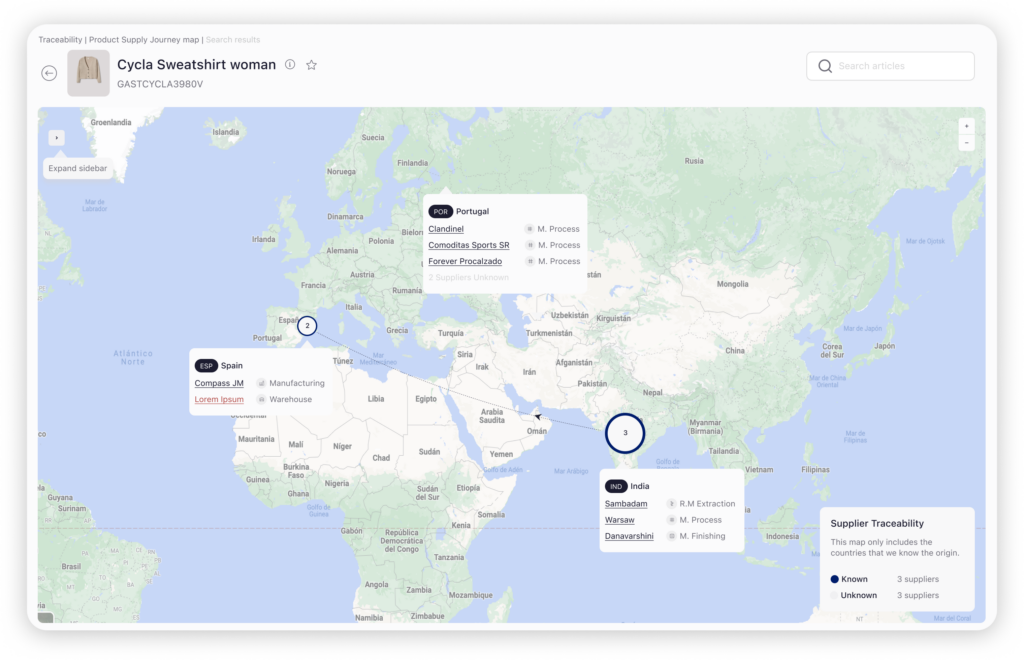

Locate your suppliers more efficiently

A PLM system that gives visibility to supplier locations can help identify opportunities to establish your value chain operations through closer partners, which would reduce transportation costs, as well as delivery times. By analyzing the geographic distribution of your suppliers, you’ll be able to strategically select those located near your manufacturing facilities or end markets. This localization approach, beyond minimizing transportation costs, also improves operational efficiency by reducing delivery times, allowing you to quickly respond to changing market demand.

Benefits summary:

- Reduction of transport costs.

- Shorter delivery times.

- Faster response to the market.

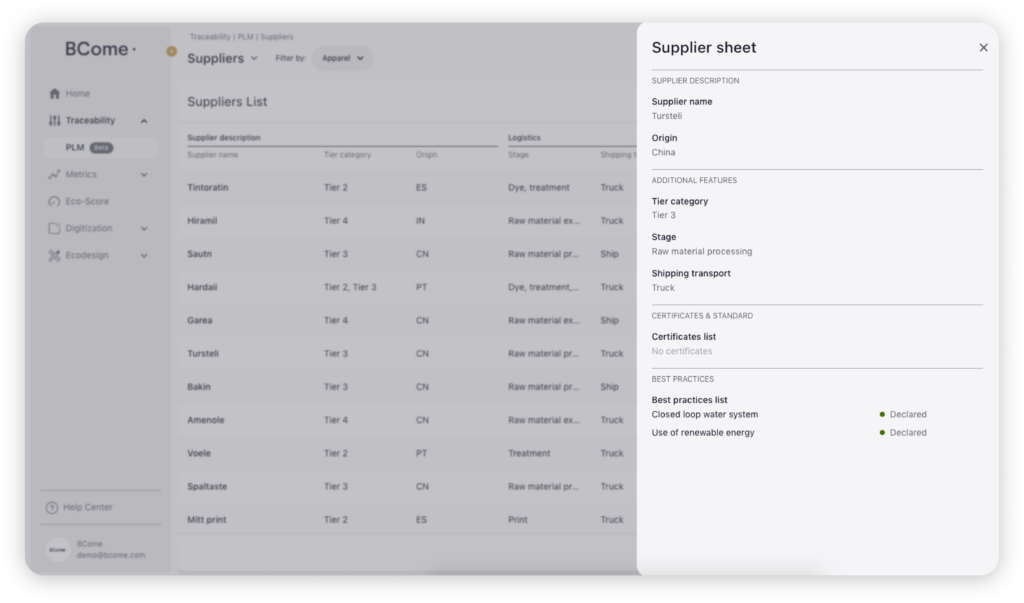

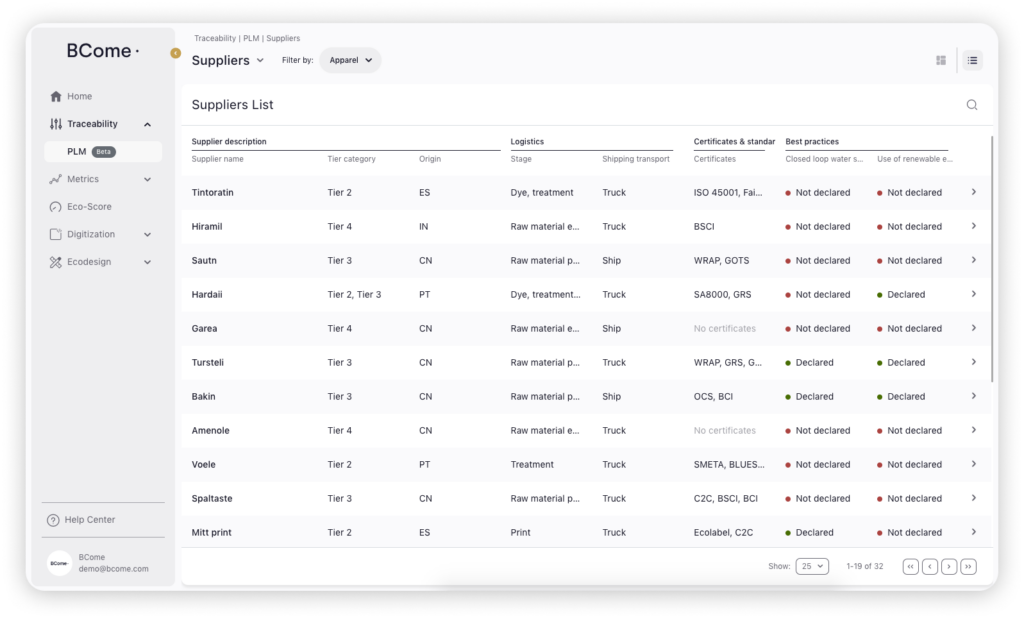

Select your suppliers based on their performance

With detailed information on best practices and certificates available to suppliers, textile companies can make informed decisions to choose profitable suppliers without compromising the quality of their product. The PLM acts as a database that centralizes all the details of your suppliers to better identify those that meet the quality standards of your fashion business. This streamlined supplier selection process not only reduces costs, but also fosters long-term partnerships built on trust.

Benefits summary:

- Identification of certificates and good practices.

- Alignment with the quality standards of your business.

- Fostering long-term relationships with suppliers.

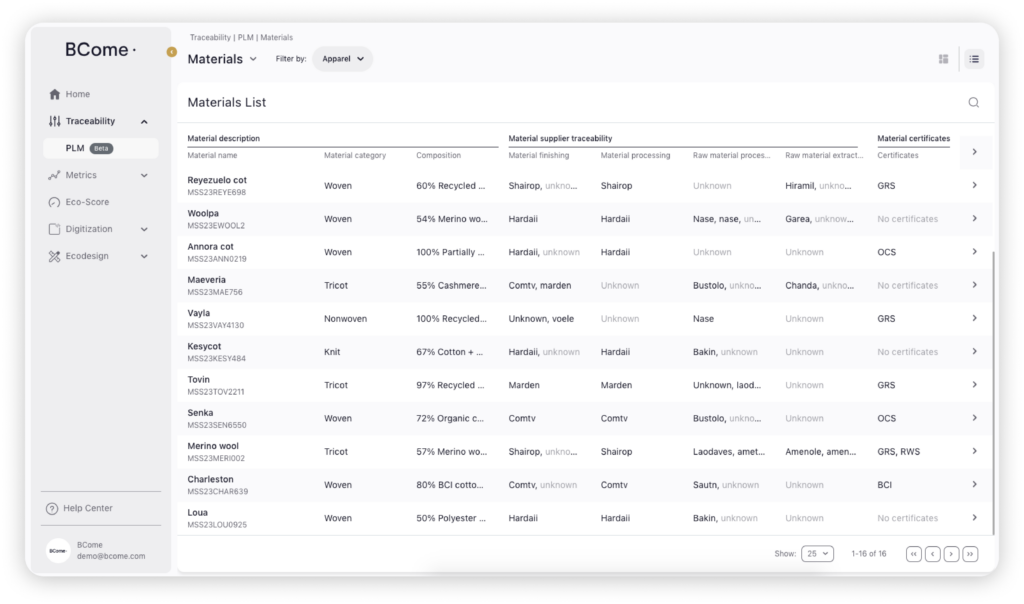

Get an optimal supply of materials

The breakdown of the materials used at each stage of the chain will help you identify profitable alternatives, negotiate better prices and optimize the use of materials, which translates into significant savings for your business. By analyzing material consumption patterns and exploring alternative sourcing options, you can discover opportunities to reduce costs without compromising product performance. In addition, BCome’s PLM tool will allow you to track and manage material inventory efficiently, avoiding excessive inventory maintenance expenses.

Benefits summary:

- Easy analysis of material consumption patterns.

- Ability to explore alternative sourcing options.

- Efficient material inventory management.

Ensure compliance with regulations

By gathering the information related to certificates and good practices, it’s possible to monitor and ensure compliance with standards and regulations. In this way, your business will be avoiding possible penalties or delays in delivery due to lack of compliance. BCome’s PLM allows companies to collect certifications and good practices implemented by their suppliers. This offers transparency on the status of suppliers and materials. By proactively addressing the level of compliance of your suppliers, you can avoid costly disruptions and maintain a good reputation in the market.

Benefits summary:

- Transparency on the status of suppliers and materials.

- Avoidance of costly interruptions.

- Good reputation maintenance.

Improve the transparency of your supply chain

Visibility into the breakdown of materials and supplier details in PLM makes it easy to identify bottlenecks, as well as inefficiencies and areas where costs can be reduced within the supply chain. By analyzing the data collected in PLM, companies can recognize where in their supply chain requires attention. Whether it’s reducing the volume of different materials used or streamlining production processes, BCome’s PLM will allow you to make data-driven decisions to improve the efficiency of your supply chain and reduce costs.

Benefits summary:

- Identification of bottlenecks and areas for improvement.

- Cost reduction through process optimization.

- Data-driven decision making.

Cost optimization in the value chain of any textile company is essential to prosper in today’s market. By using a tool like BCome’s PLM, fashion businesses can unlock huge savings opportunities. Supplier localization, optimal material sourcing, simplified compliance management, and improved supply chain transparency are just some of the ways this solution can revolutionize your traceability.

Don’t miss the opportunity to discover how this tool works in our next live demo: Introduction to BCome’s PLM. In this 30-minute webinar, we’ll guide you through the tool to learn in detail the solution that can boost traceability for your fashion company. Also, if you prefer to talk about the specific situation of your business, we invite you to book a meeting with our Sustainability Experts. Together, we will find a customized solution that suits your needs.