We’ve mentioned it several times, the environmental footprint of the fashion industry is well known. The need to move towards a circular economy is part of a common consensus that recognizes circularity as a beneficial solution for both the planet and people. However, its application continues to be insufficient. From BCOME we’ve asked some of our brave brands if they think it’s possible to scale circularity in the fashion industry. Filippa K, Ecoalf or Sepiia, among others fashion brands reveal their vision on the transformation of the sector to address the challenges presented by the reduction of textile waste.

The circular economy is positioned as the definitive system change to generate greater value creation for the industry

In the words of the Ellen MacArthur Foundation, a circular economy is one in which waste and pollution are eliminated. Products and their materials circulate and natural systems regenerate, all through design. In this way, the circular economy is positioned as the definitive system change to achieve a reduction in the consumption of virgin resources, significantly reducing harmful environmental impacts, while generating greater value creation for the industry. A clear and simple definition, but how is this put into practice? There are two major transformations needed:

- On one hand, the need to extend the useful life of products and materials through a design created for durability and reuse. This works to reduce the demand for virgin materials and, as a consequence, the reduction of the environmental impact.

“Since we founded Sepiia, making garments that are circular has become our obsession. Through the exclusive use of monomaterials, trimmings and biodegradable packaging, we ensure that everything we do can have a future life. Thanks to eco-design, which considers the entire life cycle of products, great improvements can be achieved in terms of circularity”. Fede Sainz de Robles, CEO & Founder at Sepiia

- On the other hand, we must ensure that the components are broken down, reused or recycled in future garments.

Measures supporting the progress of circularity in fashion range from designing a product to be more durable, encouraging consumers to resell or repair their garments, creating a reselling platform, or scaling up textile recycling.

The second-hand market is one of the fastest growing circular models, in particular it’s expected to double the value of fast fashion by 2030.

“GlamCorner is Australia’s premium womenswear fashion rental service. Since 2012, customers have shared over 1,000 tonnes of clothing and diverted over 10,000 tonnes of textiles from ever needing to be manufactured in the first place. We’ve just launched RELOOP – Australia’s first, full-service re-commerce platform where customers and retailers can resell, repair and recycle their garments. Buying Pre-loved helps the environment by extending a garment’s life while reducing the amount of clothing sent to landfills”. Zoe Mellick, Sustainability and Social impact Lead at GlamCorner

The EU Circular Economy Action Plan is raising the level of sustainability standards required for new products marketed in the EU. Legal measures are expected in 2023 requiring design criteria for the durability, recyclability and reuse of products.

However, despite focused efforts to achieve a circular system, the current infrastructure supporting textile collection, sorting, resale and recycling is considered to be subscale.

It’s estimated that less than 1% of the material used to produce clothing is recycled into new garments. According to Textile Exchange, cotton accounted for approximately 24% of the global fiber market in 2020, while recycled cotton accounted for less than 1%. Given these data, is there a place for large-scale circularity in the fashion industry?

“Yes it’s possible to scale circularity, and it’s imperative that we do so. The current pressures of our environment and scarce resources require the fashion industry to look for better ways to create and produce garments. Given consumers’ increasing awareness around sustainability, more and more companies are able to drive the circularity movement. There are opportunities in each step of the life cycle to make circular products (not just at the end), and we have the ability to leverage on existing technologies. We hope that with time, there will be further policies in place to help support and make this even more possible”. Jodi Everding, Fabric & Sustainability Director at Filippa K

Conditions are positive for the transformation of the sector, but progress is slow. Faced with a context that requires new strategies to scale this systemic change, we find ourselves with two great enablers:

- Financing is essential. Investment from governments and companies is still far below what is required. It’s important to consider that this investment will be an opportunity, not a cost. You will create and grow new and existing businesses.

“We must put an end to the ephemeral life of products. Investment in innovation and technology is much needed early in supply chains, to effectively sort and better recycle products, rather than throwing them away. Keep in mind that many of them end up polluting the environment. Innovation must also be at the service of creation and design to find new materials that help reduce environmental damage”. Álvaro Fiestas García-Izquierdo, Marketing and Brand Director at Parafina

- Collaboration between industry players is essential. Scaling circularity in fashion requires building new subsectors of the economy in record time. Accelerating this pace implies a collective effort so that new technologies transcend more quickly.

On the other hand, the opportunity to scale circularity in post-industrial waste is often overlooked. Although consumer waste creates the bulk of textile waste, the recycling of post-industrial waste shouldn’t be forgotten. It’s often more consistent waste, higher quality, easier to track, significantly larger, and requires much simpler sorting and collection than post-consumer waste.

“Circularity allows us to move towards that much-needed balance between our needs as humans and those of our planet. Therefore, it is something totally necessary. Circularity must scale to all actors in the fashion sector. This circularity goes through a minimization and optimization of resources, through designing and producing garments with high durability, but above all… through a reduction in consumption. Will brands and consumers be ready for this?” Carol Blázquez, Head of Innovation & Sustainability at Ecoalf

The EU strategy for sustainable and circular textiles, adopted last March by the European Commission, presents measures related, for example, to Extended Producer Responsibility (EPR) and incentives for innovation with the aim of promoting sorting, reuse and recycling of textiles, ultimately limiting overproduction.

“Instead of exploiting resources, consuming them, and then throwing them away, we must learn to revalue them at the end of their life through donations, upcycling, or recycling. However, for this circularity to become concrete, the textile industry must reinvent itself, setting up dedicated logistics with the creation of adapted and local recycling channels as well as an efficient upstream sorting method”. Clara Jublan, Communication Manager at Weturn

The role that consumers play is also essential to achieve the rise of circularity. The industry needs to encourage people to buy products made from recycled materials, motivate them to make their clothes last longer and, most importantly, encourage clothes to return to the production cycle at the end of their useful life.

“Fashion must invent a new norm made of slower rhythms focusing on circularity, leveraging textile waste and recycled materials as prime materials for future collections. At Scandale éco-lingerie, 80% of our yarns come from recycled origins. We made our circularity dream become a reality, knowing that it’s just the beginning”. Edouard Roche, CEO at Scandale éco-lingerie

In this sense, few countries have expanded the infrastructure for the collection and classification of textiles. The lack of this structure is a limiting factor for the post-consumer recycling of many brands. The introduction of Extended Producer Responsibility implies that brands and manufacturers take responsibility for the end of the useful life of their products, both physically and financially. The EPR seeks that the manufacturer benefits from the design of more durable products, as well as being easier to recycle into high quality final products.

“At Infinite Athletic we create a new 100% recycled and 100% recyclable garment from the collection of used tennis strings. Brands have to think in a circular way from the selection of materials and design, two fundamental stages to achieve a total circularity of the product. There is no such thing as perfect circularity, but big brands need to start implementing pragmatic solutions into their existing collections”. Francois Devy, Co-founder at Infinite Athletic

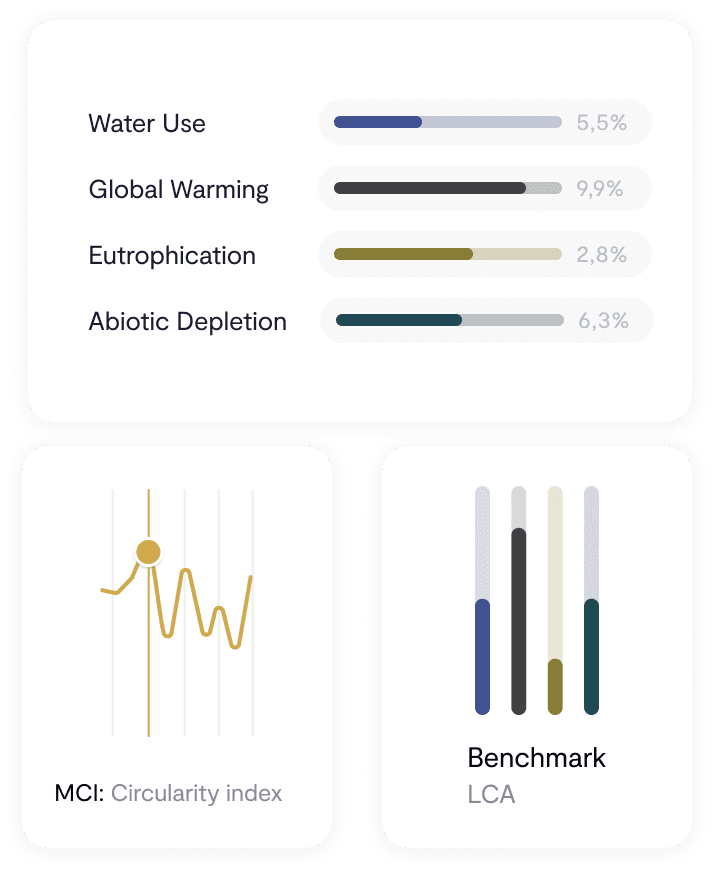

Collaboration between companies within the fashion industry is a powerful model for achieving circularity in the sector. At BCOME we want to join your business so that together we can tackle the transformation of the textile ecosystem towards a more circular model. Our brave brands already integrate our tool in their decision-making to create more sustainable products. Do you want to be part of this great community? Let’s talk!